So I posted in a separate topic how I upgraded my Max V2 to an all-metal kit from Matthew (more well-known as travelphotog here at the forums) at 713Maker, but it took me a while to receive some filament to print a mount for my PanelDue 7i that also went in during the upgrade.

For those that haven't stumbled across that post about my upgrade, it can be found

here.

To update that post, rather than bumping his topic, and since it really has nothing to do with his kit specifically, I figured I would post photos of my mount here.

I used SeeMe's original STL files for the RepRapDiscount LCD mount, and modified them to be compatible with

THIS PanelDue 7i case from Thingiverse. I used a thinner case variant shown

here, but the back piece that matters for mounting is equivalent on both models.

- For anyone who was unfamiliar with why my printer is named "W.I.S.P.E.R.", I placed a helpful reminder on the boot screen of the PanelDue 7i.

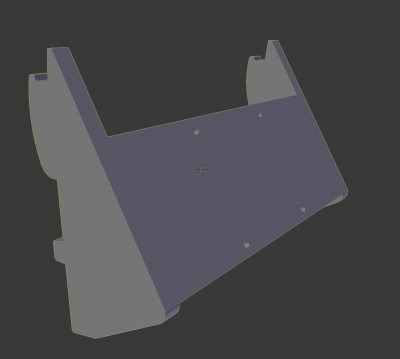

- From this angle, it's easier to see that the SeeMe files were used. I essentially just joined the two angled brackets together onto a single solid backplane, that then gets attached to the rear of the PanelDue case, taking advantage of the 4 mounting holes originally used by the model designer to attach an arm bracket.

- My setup utilizes the same angled offset that the RepRapDiscount LCD had, due to using the original SeeMe files to make the mount.

- A screenshot of the rear mount that I modified to work with the PanelDue 7i's case

If you have any questions, just ask, and I'll try my best to answer them. The only reason I am not posting the rear bracket STL file, is because I was rather lazy in how I modified the SeeMe brackets in Blender. The model has non-associated faces which didn't want to play well with my usual slicer software (CraftUnique's Craftware) and was thus printed using Cura.

I am quite happy with how the finished product came out!

If at first you don't succeed, you're doing something wrong. Try again, and if it fails again, try once more. Through trial and error, one can be the first to accomplish something great.