Page 1 of 1

Z Probe PartDaddy Style

Posted: Tue Nov 11, 2014 6:34 pm

by PartDaddy

I'm not sure if others have designed a probe like this, but here's how I'm going to make the hardware. Pics soon. Just throwing this idea out there.

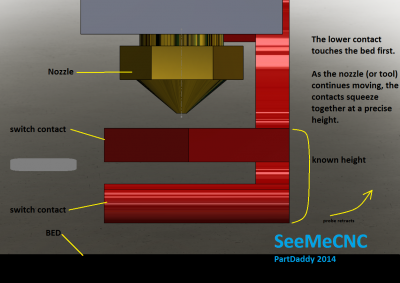

On the platform, a probe would deploy by the tower swipe method (or servo). The probe is switch activated and makes physical contact with the bed. The difference is the position of the probe. The probe needs to be between the nozzle tip and bed. Level and Z is set by four point probing, then 3 points in a straight X axis would allow for horizontal radius calculation. My reasoning for 4 points, then 3 is because eeprom would probably need read and wrote to twice. However, this is where clever programming comes into play.

Positioning the probe sensor (switch, or switch mechanism) between the nozzle tip and bed eliminate manufacturing tolerance of hot end parts and bed thicknesses. As with any machine tool, it is important to build your machine as square as possible.

Re: Z Probe PartDaddy Style

Posted: Tue Nov 11, 2014 7:14 pm

by Polygonhell

FWIW I'm not sure how much value there is in automated deployment. How often do you really need to make the measurements?

I have a probe on my Mini Kossel, and I when I want to bother with calibration which is rarely I manually deploy it, the physical dimensions of the machine just don't change much. a clip on probe might even be a good way to go.

Certainly having the probe as close to the nozzle position as possible is a win, and I like some of the use the hotend to trigger a switch mechanisms where there is effectively 0 displacement, but for simple Delta Radius calibration it isn't "necessary"

Re: Z Probe PartDaddy Style

Posted: Wed Nov 12, 2014 1:42 am

by Jimustanguitar

Polygonhell wrote:How often do you really need to make the measurements?

I move my printer constantly, and I'd do this any time that I felt like I jolted or tweaked it.

Re: Z Probe PartDaddy Style

Posted: Wed Nov 12, 2014 10:35 am

by geneb

IMO, automatic deployment is nice, but might make a simple thing overly complex to build. Frankly, I REALLY like the FSR (force sensing resistor) method that has become popular for doing a z-probe. It's always there and there's nothing to deploy. There just needs to be a way to use it with the MAX that doesn't let the high bed temps needed for ABS damage the FSRs.

g.

Re: Z Probe PartDaddy Style

Posted: Wed Nov 12, 2014 10:50 am

by Nylocke

Rpress's method of mounting seems pretty good. There's the whole bed insulator and and chunk of aluminum between the sensors and the hot thing. You'd have to ask him how well it works, but I've ordered the FSR's ($30 isn't too bad) and I'm going to try and make something like what he's done up.

Re: Z Probe PartDaddy Style

Posted: Wed Nov 12, 2014 10:57 am

by PartDaddy

Polygonhell, your post is spot-on as usual. Calibration certainly doesn't need done very often. For those skilled, a probe will be a time saver (and fun). Someone might want to quickly swap out build surfaces and thicknesses. Or swap hot ends. I want it for the time saving aspect.

Looking forward, one goal is to allow ease of use for newbies. And reduce our customer support workload for our assembled machines. Even on a less expensive machine, many customers will use the printer long enough until a new hot end is needed. At that point you gotta unplug the old hot end, plug in the new one and calibrate. Getting that first layer right it very important to a successful print.

Regarding general user skills, I view the state of 3D printing today as still requiring an "intermediate" skill. It's not advanced, but on the cusp of "novice".

Re: Z Probe PartDaddy Style

Posted: Wed Nov 12, 2014 12:07 pm

by Polygonhell

I agree entirely with the new user scenario, if the goal is to set Z = 0 with it, I think you will want an always "deployed solution" that uses the hotend itself as the probe, which leaves you with either FSR's which have there own issues or other sensors under the bed, or some sensor or switch in the hotend holder.

Any deployed solution would have to know at least the Z displacement from the hotend 0, which obviously would change if hotends were changed, requiring user intervention.

Re: Z Probe PartDaddy Style

Posted: Wed Nov 12, 2014 2:55 pm

by Polygonhell

Thinking about this I'd be tempted to mount the hotend like one of those touch probes you can get for CNC mills (like this

http://www.craftycnc.com/touch-probes/ or this

http://www.vinland.com/touch-probe.html), basically the probe is spring loaded with 3 ball bearings closing a circuit on the receiver which has "divots to align it". It has the nice property that you can use it for both vertical probing and X/Y probing, though without knowing the tool radius it's a bit pointless.

Though the issue might be producing the parts accurately enough with enough volume.

Re: Z Probe PartDaddy Style

Posted: Wed Nov 12, 2014 4:15 pm

by Generic Default

I like the idea of having the probe detach from the end effector while not in use, but having an integrated sensor is cool too. Here are a few of the methods for probing I'm aware of;

1) Limit switch contact with bed

2) Electrical conduction with bed

3) Magnetic proximity to bed

4) Pressure contact with bed

But all of those have problems.

1) The limit switch means the nozzle can't touch the bed during probing (unless it is attached to the hotend so the hotend is free-floating in a limited way)

2) The bed must be conductive. Non-metal beds prevent this, but metal beds don't let plastic stick.

3) There must be steel (magnetic) components, which don't work with heat so well.

4) The sensor can't get too hot apparently

None of the solutions work when the build chamber is closed and hot, which will be a design necessity once the patent for it expires in a few years.

I was thinking of putting limit switches or electrical contacts on springs under three sides of the bed, then having a rigid end effector press them down to contact. So the printer would home to the bottom instead of the top. Of course this requires some basic pre-calibration to get the probing close to where it needs to be.

Re: Z Probe PartDaddy Style

Posted: Wed Nov 12, 2014 4:25 pm

by Nylocke

Your point about the heated chamber gave me an idea for the FSR mounts, assuming that the base is cooled and is a good place for electronics still... I'll try it out on mine when I get my sensors and post my results. Should keep them nice and cool.

Re: Z Probe PartDaddy Style

Posted: Wed Nov 12, 2014 10:17 pm

by bdjohns1

Generic Default wrote:I like the idea of having the probe detach from the end effector while not in use, but having an integrated sensor is cool too. Here are a few of the methods for probing I'm aware of;

1) Limit switch contact with bed

2) Electrical conduction with bed

3) Magnetic proximity to bed

4) Pressure contact with bed

But all of those have problems.

1) The limit switch means the nozzle can't touch the bed during probing (unless it is attached to the hotend so the hotend is free-floating in a limited way)

2) The bed must be conductive. Non-metal beds prevent this, but metal beds don't let plastic stick.

3) There must be steel (magnetic) components, which don't work with heat so well.

4) The sensor can't get too hot apparently

#2 is easily solved for. Use a metal block of known thickness wired through the hotend and set it on the bed. That's how some CNC mills "touch off" to find their zero when you're milling something non-conductive. 1-2-3 gauge blocks are generally good to 0.0005", right?

Re: Z Probe PartDaddy Style

Posted: Wed Nov 12, 2014 10:22 pm

by Generic Default

The metal plate would either have to be big enough to cover the whole bed, or you would have to slide it around for each probe point. I used a shopbot router a few years ago, and the Z height was set with a plate like that. It's kind of a pain to do, and it isn't that accurate. Plus the plate would cost quite a bit for a delta printer.

Re: Z Probe PartDaddy Style

Posted: Thu Nov 13, 2014 8:40 am

by PartDaddy

Here's a quick drawing to share the idea.

- PartDaddy's Z Probe

Re: Z Probe PartDaddy Style

Posted: Thu Nov 13, 2014 9:41 am

by geneb

Generic Default wrote:The metal plate would either have to be big enough to cover the whole bed, or you would have to slide it around for each probe point. I used a shopbot router a few years ago, and the Z height was set with a plate like that. It's kind of a pain to do, and it isn't that accurate. Plus the plate would cost quite a bit for a delta printer.

You may have worked with a poorly leveled ShopBot. I've got a PRT Alpha 96 I've had since 2007 and the Z height plate isn't a pain to use, nor is it inaccurate. I've regularly used my machine with stupidly tiny V bits to make two sided printed circuit boards.

I also have a precision machined 1-2-3 style aluminum block that I use to zero my x, y and z axes at the same time. Works using the same circuit as the Z probe plate does.

g.

Re: Z Probe PartDaddy Style

Posted: Thu Nov 13, 2014 10:36 am

by teoman

Have a look at artmxg's calibration thread. We were almost on to something there...