Page 1 of 2

Making an aluminum base and top, Need Your Feedback

Posted: Wed Jul 24, 2013 5:45 pm

by JohnStack

Hi,

I've started on a design for an all aluminum base/top for the Rostock Max. I'm not sure I'm going to sell them but I am considering that as well.

To come up with a design, I have some features that I would like to include as well as features that I probably should include but haven't considered.

Without embarrassing myself with a drawing, here is the description:

Bottom:

The base does not include electronics. Those are held in a separate box. (TBD but Hammond has some decent ones)

Six plates or wings coming off of a center object. (The center is likely to be a triangle.)

Each wing slides into a slot in the center triangle and is affixed with hex cap machine screws.

T-bars slide in between each pair of wings and are keyed. The keys leverage the side slots of the t-Bar.

T-Bars bottom out so no calibration, 100% precise. Set screws hold the T-bars in place.

Steppers and Rollers are the same config as the Rostock Max.

Top:

The top essentially mimics the bottom except in reverse except the end stop switches screw into the top.

Belt handling is essentially the same.

Other features:

To support the Onyx, a 3/8" aluminum ring will screw into the top of the base. (Anything I should do for heat loss?)

Questions:

I am considering other nice to haves. Please let me know if you would do this:

Pre-drilled holes in the top 'wings" spaced every inch - on top and bottom so that other things can be mounted (EzStruder), spool

Some kind of tribal design cut into the wings on the top and bottom - just to give it an edgy look.

Anodizing.

Belt Tensioners (I've never had an issue here.)

Precise base leveler

Aluminum Bubble Level

Why am I doing this?

I want to see if there is demand for a base. If there is, I'll make them - but only if it is profitable. I have access to a high volume CNC shop.

What am I missing? If you were doing it, what would you add? Beyond Barry Werner's, ave you seen any that are really great?

Your ideas are really welcome here. I would love to design the end all machine here - both to take advantage of opportunities as well as nip a few things in the bud. Maybe you've done one yourself! If so, let me know!

Also, if you've seen a commercial looking box that would be suitable for the rambo and a 600W power supply, let me know.

THANKS!!!

Re: Making an aluminum base and top, Need Your Feedback

Posted: Wed Jul 24, 2013 10:59 pm

by ApacheXMD

I think you could fit all the electronics in a base since you have to allow for the height of the stepper motors.

I think you could easily have an external 12v power supply and have everything else self contained. That way external wiring would only be a single pair of wires instead of a huge wiring harness for all 4 steppers, thermistor(s), hotend(s), endstops, fans, lights, etc.

Re: Making an aluminum base and top, Need Your Feedback

Posted: Thu Jul 25, 2013 11:17 am

by JohnStack

ApacheXMD wrote:I think you could fit all the electronics in a base since you have to allow for the height of the stepper motors.

I think you could easily have an external 12v power supply and have everything else self contained. That way external wiring would only be a single pair of wires instead of a huge wiring harness for all 4 steppers, thermistor(s), hotend(s), endstops, fans, lights, etc.

Thanks, looking at PS Options now. I was hoping to have fairly clean looking base; however, I've concluded that cable length and noise are too big a factor to ignore.

The other design goal was to take 100% of SeeMeCNC's BOM w/o about 98% of the melamine and use it. I'm close. I think I would keep the cheapskates as they are...

Closing in on something very soon...

Re: Making an aluminum base and top, Need Your Feedback

Posted: Thu Jul 25, 2013 12:37 pm

by lordbinky

Since the T-bars are so critical, have you considered having the base's wings allow for slight pivoting (toward and from the triangle) and have the top wings have some keying that you can lock in. You lose the potential for no calibration of the T-bars, but you give yourself alot more flexability in machining tolerances for not only your parts but the T-bars as well. Since the structure would be so rigid it is very likely that you would only have to perform that calibration once.

Re: Making an aluminum base and top, Need Your Feedback

Posted: Thu Jul 25, 2013 4:39 pm

by JohnStack

The wings will be cut in one run using a Haas VMC 6/40 TR. I'm going to give no adjustment a try first and then if required, something else.

Assuming the T-bar is straight, I'm hopeful that tweaks like this can be avoided - as well as something to keep the bed on the level.

I've considered asking for a change in the Onyx design to accommodate more screws - like in the center - but I have also talked to other folks who can make same/similar independently heated beds for about $200. Not sure here.

Funky discovery:

Off of the repo: Rambo board holes distance between each other: 95.25 x 96.52? Verified on the board itself.

Bad juju me thinks.

Re: Making an aluminum base and top, Need Your Feedback

Posted: Thu Jul 25, 2013 7:55 pm

by lordbinky

JohnStack wrote:

Funky discovery:

Off of the repo: Rambo board holes distance between each other: 95.25 x 96.52? Verified on the board itself.

Bad juju me thinks.

More like someone had bad ujuj.

Re: Making an aluminum base and top, Need Your Feedback

Posted: Fri Jul 26, 2013 3:12 am

by kbob

I don't really understand why you want a different base, John. How do you expect this aluminum base to be better than the melamine base? Will it be better looking? Smaller? Bigger? More rigid? Heavier? Lighter? Easier to assemble? More exclusive?

Have you looked at the Cerberus printer? (Cerberus is a great name, BTW.) Does it have anything in common with what you want to do?

Yes, I am sore confused.

Re: Making an aluminum base and top, Need Your Feedback

Posted: Fri Jul 26, 2013 9:30 am

by JohnStack

Hi!

I've seen the Cerberus. Good, minimal design.

Think of the delta printer as part of a larger triangle: software, hardware, and design of objects.

Melamine is one market. That almost sums it up that aspect of it. I tend to think if if you remove the majority of dynamics of its use, then with the right enclosure and software, you nudge delta printing to a standard worthy of adoption in aerospace and other industries. Lofty, maybe. There are other guys working on metal case designs too, I just thought it would be worth it to ask the community.

Alternatively, it was either this or watch TV.

Re: Making an aluminum base and top, Need Your Feedback

Posted: Fri Jul 26, 2013 1:33 pm

by lordbinky

Melamine is nice and all, but at it's... core

it is still particle board. From a straight materials outlook, the biggest disadvantage I see for aluminum as a replacement material is that it is conductive, otherwise it is pretty much superior to melamine in every way especially *cough* ignoring price *cough*.

As for design improvements, for every question kbob asked the answer is 'it can be'. It depends on what johnstack does. With the design he proposed so far the enhancements are simpler assembly and fewer adjustments/alignments. Depending on the thickness of the aluminum it could be bigger, sturdier, and likely heavier than the rostock max. As for being better looking, he did mention decorative designs in the structure but it can go beyond that with options like color anodizing.

I also see the potential in his described design for simple but significant upgrades, such as extension segments for the wings. This would allow him to offer aluminum extensions to increase print area with a new set of arms (I guess for ABS you'd have to upgrade your heated bed to...). I think there is some spiffy potential with the design.

Re: Making an aluminum base and top, Need Your Feedback

Posted: Sat Jul 27, 2013 11:58 am

by JohnStack

Had these, just didn't post them.

Design Goals:

Accessible (Visually/Physically) Everything (Electronics, wires, etc)

Stable - Reduce Environmental Sensitivity (Moisture, Temp)

Rigid - Reduce sensitivity to movement from the device and environment

Precise - Predictable heights/widths (within 5 microns hopefully)

Extensible - Just like the Max, easy to modify / extend with covers, shielding, other mods

Minimal - In build time, configuration, looks

Aesthetically Acceptable - Acceptable to companies, shops looking for something beyond a kit - even though it is one

Re: Making an aluminum base and top, Need Your Feedback

Posted: Sun Jul 28, 2013 4:17 pm

by foshon

I would worry about depending on the squareness of the extrusion cut to determine upright location. Possibly some sort of set screw adjustment (in two directions).

Re: Making an aluminum base and top, Need Your Feedback

Posted: Mon Jul 29, 2013 3:02 pm

by JohnStack

Hi!

Good suggestion. We'll see what we can do. Have a couple of ideas. Hoping for a mostly finished model with photos by late next week.

Re: Making an aluminum base and top, Need Your Feedback

Posted: Tue Jul 30, 2013 2:17 pm

by JohnStack

Ok, I've got the wing design almost set - but I have a GINORMOUS question:

How do you recommend running the wiring for the hot end and extruder? I'm going for an ultra-clean look...

Right now, my plan is to run it all through two of the uprights (barely fits but does) and have the bowden tube and hot end wiring arch between one of the uprights.

Also, a second Max is on the way - so the project is looking like I'll have something to post the week after next!

Re: Making an aluminum base and top, Need Your Feedback

Posted: Tue Jul 30, 2013 4:56 pm

by kbob

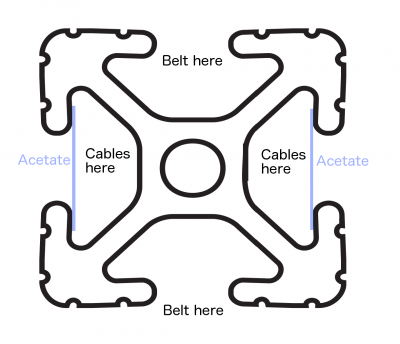

Run it through the side channels in the extrusions. Cover them over with a strip of acetate or something similarly thin and stiff.

- Like this.

You'll have to figure out how to route it so it doesn't go under the bolts and T-slot nuts. Or maybe you can use bolts short enough that they don't protrude past the nuts. 80/20 also sells thinner nuts.

Re: Making an aluminum base and top, Need Your Feedback

Posted: Wed Jul 31, 2013 6:38 pm

by JohnStack

I would do that; however, I'm using the side slots. They're sliding over keys in the wings. That gives it rigidity/precision.

Maybe starting routing wire above the keys.

And now to source 6.6mm acetate strips... LOL

Re: Making an aluminum base and top, Need Your Feedback

Posted: Thu Aug 01, 2013 10:26 am

by geneb

Use one of these:

http://www3.towerhobbies.com/cgi-bin/wt ... LXAA63&P=0 to cut strips of the material. Should work great.

g.

Re: Making an aluminum base and top, Need Your Feedback

Posted: Thu Aug 01, 2013 3:20 pm

by JohnStack

@Geneb, I believe I'll be leaving that to the builder!!!

Re: Making an aluminum base and top, Need Your Feedback

Posted: Thu Aug 01, 2013 4:08 pm

by geneb

Chicken!

g.

Re: Making an aluminum base and top, Need Your Feedback

Posted: Thu Aug 01, 2013 4:39 pm

by Eaglezsoar

I wonder, a hen or a rooster?

Re: Making an aluminum base and top, Need Your Feedback

Posted: Thu Aug 01, 2013 5:31 pm

by lordbinky

Squirrel!

Re: Making an aluminum base and top, Need Your Feedback

Posted: Thu Aug 01, 2013 6:53 pm

by JohnStack

Just about done with the design; however, I have one question:

If I were to sell this, what is a reasonable retail price? I expect that we'll have about $250 in materials/machine time in them. We're planning on heat-treating or cold working the aluminum so that it won't "slip" as much if it heats up - that cost is still outstanding; however, the rest of the costs are within that.

Re: Making an aluminum base and top, Need Your Feedback

Posted: Fri Aug 02, 2013 4:27 am

by ApacheXMD

To be honest, I'm not sure there is much of a market for this. Folks who already own a Max probably don't want to do a complete teardown/rebuild of the machine once it's up and running. At $250+markup you're probably limited to selling to those building a new printer from scratch, i.e. not from a kit. And for those folks, your part will probably have to be very compelling for them to choose it over Johann's standard Rostock or Kossel design.

I don't mean to be a wet blanket, and I fully encourage you to improve upon your printer, but I wouldn't get my hopes up in selling a bunch of these.

Re: Making an aluminum base and top, Need Your Feedback

Posted: Fri Aug 02, 2013 2:35 pm

by JohnStack

That wasn't the primary intent - to sell them; however, after shipping about 20 products in various markets (hardware, software, consumer goods), having the discipline to collect feedback from existing consumers is extremely valuable.

W/RT product, most of everything I've seen is oriented towards kit builders - as a finished product. The design goals include teasing out the notion that the base Rostock might not work for a commercial operation - there are few Deltas out there that engender that level of trust. I've had feedback from three design shops and two aerospace firms that they're interested in Deltas; however, there aren't any products out there that they'd put in their shop right now. Perhaps this is a step in the right direction.

More on this: The feedback I have had is that if they can stay under $2,500 for a completed machine, they're good.

W/rt products, I've built things that would never get commercialized just to chase down a notion. I'm good with it - in fact, it helps me come up with other things.

As for the rest, as I've said before, I'm extremely grateful to people who share their opinions on this.

Re: Making an aluminum base and top, Need Your Feedback

Posted: Fri Aug 02, 2013 4:09 pm

by Eaglezsoar

John, when are we going to see a drawing of your ideas?

Re: Making an aluminum base and top, Need Your Feedback

Posted: Fri Aug 02, 2013 4:10 pm

by lordbinky

My opinion: Price is really hard to narrow down, especially when you have additional process costs. In 3 departments of engineers (~70 people) I know of only two that would notice right away any missing but useful treatments that aren't explicitly necessary for the application. This is excluding processes that contain 'Oh shiny!'* factors to them which in my opinion sway far to many of the remaining 68 in their opinion (like colored anodizing vs clear anodizing), I'm not talking bad about anyone it's just human nature and I find it silly to not account for it. So the increased cost out of any additional processes that do not have superficial elements to them ('Oh Shiny! factor'), only add value to the end product if those processes will affect the final product such that vague qualities customers assign the product such as 'reliability'. When working with less technical people, in my head that is classified as the 'Just Works' factor. So it is really really dependent on how significant those processes impact the final result.

tl;dr

Increased costs dissuade some people, any extras have to impact the result enough that people dissuaded by the increased costs (Pd) are made up for by the satisfied customers(Ps) and the customers they bring in by word of mouth(Ps friend's). Pd < (Ps) + (Ps friends)

Even if you're intent is not sales, this line of thinking keeps my feature/design creep in check, at least until I decide to ignore it.

*You can increase price to ludicrous amounts for any process that adds 'Oh, Shiny' factor if you allow the customer to justify it to themselves. I can't even try to quantify this...