Page 1 of 3

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Tue Aug 05, 2014 3:34 pm

by Eaglezsoar

travelphotog wrote:Thanks! I had a great time doing the build. Though the more time I spend here the more things I want to change. I wish I had 2 rostocks, one for printing and one for R & D. Might have to make that happen in a month or so...

But after seeing the E3D PCB mount pics I might be hitting the computer and making some upgrades of my own this weekend. I make PCBs for my Arduino projects all the time. This gave me a few ideas! In a short time I am picking up a desktop CNC mill for PCBs as I make so many. I am looking forward to exploring this concept and seeing where I can take it on my MAX.

I am changing out the RAMBO fan today for a Noctua 60mm and adding a Noctua 92mm on the side for over all lower bay cooling. I am really looking forward to ditching the loud RAMBO fan and keeping things nice and cool over all.

I did a few other upgrades and will try to dig up the pics and get them posted shortly. I think today is mostly going to be a design day though over all. Have an 11 hour print to knock out so CAD day it is!

May I ask which desktop cnc mill you are going to be getting?

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Tue Aug 05, 2014 9:14 pm

by travelphotog

Since my main use the CNC will be PCB etching and some light 6061 aluminum milling, I have chosen the Shapeoko 2 with a 400W spindle ( router is too our for inside my office ). Oddly enough it was a story I saw on the Max v2 while researching Shapeoko that lead me to buying the Max v2 and getting into 3d printing. I discovered that i would need a housing for the TinyG CNC controller and also end stop switch mounts and such. All of which could be printed out on the 3D printer. I also soon saw how useful it would be for my Reef LEDs and Arduino projects.

I wish I had the budget and space for a larger and more powerful CNC mill, but that is just not the case. For the PCB etching ( I am SO sick of acid etching boards 24/7 ) and the little it of aluminum milling I want I think the Shapeoko 2 will get my by for now.

Right now I am waiting on a client to settle up on a large build I did for them of a remote camera dolly system and 20ft of black anodized aluminum trackway.

- This was my last project and will pay for the CNC

Once that project is finished up I will be grabbing the CNC and putting it to work straight away!

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Tue Aug 05, 2014 10:28 pm

by travelphotog

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Wed Aug 06, 2014 2:06 am

by travelphotog

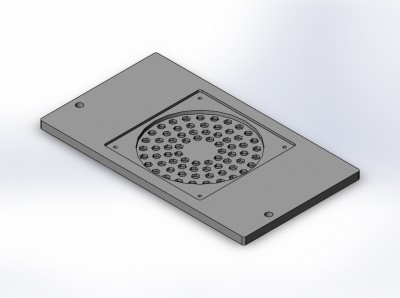

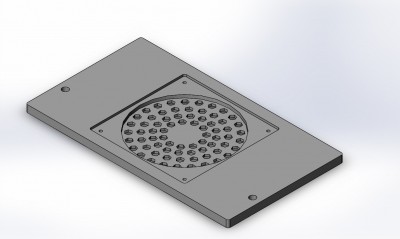

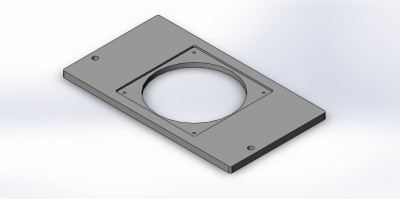

- Knocked out the replacement side panel with fan mount in CAD tonight. Waiting for a 9 hour print to finish so I can give this a try and see if I can mount the new fans tomorrow night.

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Wed Aug 06, 2014 8:30 am

by Eaglezsoar

travelphotog wrote:Max side Panel 92mm fan 1 CS GUARD R1 2.JPG

Max side Panel 92mm fan 1 CS GUARD R1.JPG

Would you be willing to share the STL for the side panels?

They would work great for additional cooling.

Also, when you print with nylon, what do you use to help adhere the nylon to the glass?

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Wed Aug 06, 2014 3:20 pm

by travelphotog

I am test printing the panels today. Once I am sure they are good I will be very glad to release them without issue. I'm still a bit new at making STLs so I want to triple check my work before I give someone a file that could have an issue.

For the nylon I used the Purple Gluestick and it worked very well. I almost had an issue getting the solder holder base off the print glass. So I guess that is good.

As soon as I have the first panel printed I will throw the files up here. let me know if anyone wants another sized fan opening. Right now it is set for a 92mm fan wit 6-32 screw holes for the fan mount. Rest of the panel is stock Rostock size.

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Wed Aug 06, 2014 6:41 pm

by travelphotog

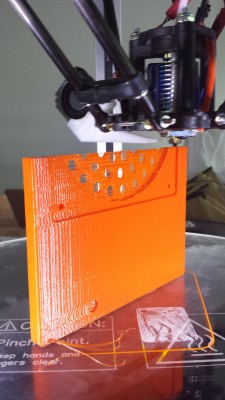

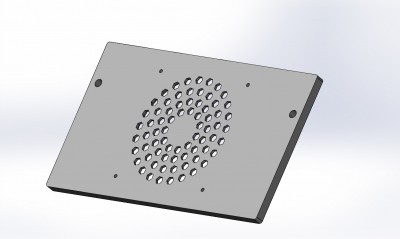

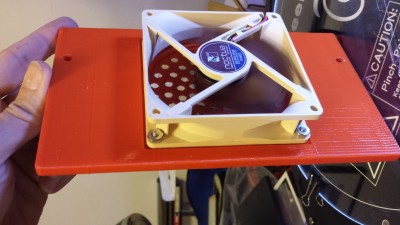

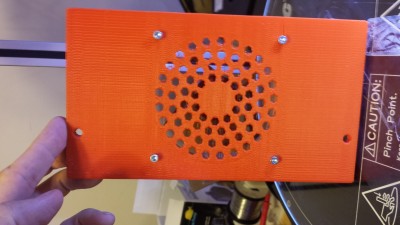

OK here are the files. I only have red PLA on hand and this is also my first ever print in PLA. But the panel looks great and everything lines up the way I wanted. This file is for adding 92mm fans in the Max V2 lower side panels. One file has the fan guard and one does not. I will post a few render images also so everyone know what it looks like. The fan mount screws are for a 6-32 screw.

- This is my first print in PLA so be kind! But here is the panel at about 47% or so.

Here are the files for the panel with a guard:

- Front side

- Back / Fan side

Here are the files for the one without a guard:

- Fan side. Front side is plain.

If anyone needs another size fan I could whip it up overnight or in a day or two.

Hope it helps someone out.

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Wed Aug 06, 2014 11:54 pm

by travelphotog

So my fan panel printed out great today. It was my first tall and thin print so I was excited to see it come out perfectly. I installed the fan at first pulling air into the base. I then noticed that my bed had a hard time getting to temp for nylon... I turned the fan around to pull air out of the base and the bed heated right up as before. Guessing the fan was blowing cold air up the hole in the middle of the base plate and cooling the bed too much. It is now pulling out nice warm air and keeping things nice and cool inside.

- Nice print overall for a first ever PLA

- Back side

- Front side

- All mounted. Thinking of doing other side in Nylon and trying a black die on it.

Tonight is the printout of the new LED holders... I did not like the ones I found so I redid them in Solidworks today and will print them out tonight while I work on the enclosure setup in CAD tonight. Also tomorrow the first LED idea for the print plate will arrive... My 5730 LEDs will arrive shortly so i will mbe knocking out the PCB ring for that this weekend I think. I think I have a thing for LEDs and lots of light where I work from being around my reef tank LEDs and being a photographer.. We tend to like light I guess.

Let me know if anyone needs a different size fan for panel, finds an issue or wants a tweak to the design. Always glad to help out where I can.

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Thu Aug 07, 2014 8:39 am

by dtgriscom

Those fan guard holes look much too small to allow free airflow. Unless you're running the fan at low voltage to slow it way down, you might want to make them larger, or switch to a lattice pattern. Otherwise you're likely to get more air noise and less airflow than you'd like.

Dan

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Thu Aug 07, 2014 9:56 am

by Eaglezsoar

After looking at it mounted I have to agree with Dan, the holes are too small. The lattice would probably work best to have more open area rather than solid plastic.

The idea is to open it up as much as possible yet a small amount of lattice only to protect from youngsters from sticking their fingers in.

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Thu Aug 07, 2014 10:56 am

by travelphotog

Yeah after seeing it in person I also can see that the holes might be a bit small. It is moving a good bit of air but I can see that larger holes or long slots would give more flow. Also working on an intake for the other side which is a little more low key. If it pans out I will post it for you guys to look at. I should have the new panel up by lunch time in Texas.

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Thu Aug 07, 2014 2:22 pm

by nitewatchman

I added two 80mm Fans from CoolerGuys via Amazon (

http://www.amazon.com/gp/product/B002NV ... UTF8&psc=1) to my rear panels to solve the same problem. Since adding these exhausting air from the base the components including the stepper are cool to the touch.

I took the two panels to my Tormach 1100 and the 1100 introduced them to "his little friend" a 1/8" end mill. This cut the opening to fit the fan inner surfaces and bolt holes. A second screen (

http://www.amazon.com/gp/product/B0014W ... UTF8&psc=1) was fitted to the hole with the grill turned in and bolted. This was then connected to a 5VDC tap on the modular power supply. The fans start with the main power switch and are silent, no motor or wind sounds.

Works well for me - Your Mileage May Vary.

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Thu Aug 07, 2014 3:04 pm

by Eaglezsoar

Very good job! That looks highly professional.

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Thu Aug 07, 2014 6:06 pm

by travelphotog

That does look very nice! If I had my CNC already i would have loved to do it that way. I had a few "shut downs" wile idel right after the build.. i removed the side panels and this seemed to stop it. Lacking my CNC ( in a few weeks or a month I hope to change that) I did a crash course in Soildworks and tried my hand at it. I am still working on the changes you guys asked for. I got called away from the house for a shoot at the last second so I had to run. I am printing a test of the new panel I worked on last night. Once I get dinner taken care of I will see about the changes for you guys.

I got a bunch of goodies today also. New RAMBO fan, 2 LEDs to test out for the printing head area and my carbon fiber spacers came in today! SUPER excited about those spacers! I had to hunt for the style I wanted and they look GREAT! Pics soon.

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Sun Aug 10, 2014 12:24 am

by travelphotog

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Sun Aug 10, 2014 12:54 am

by nitewatchman

travelphotog wrote:That does look very nice! If I had my CNC already i would have loved to do it that way.

What CNC Mill are you getting?

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Sun Aug 10, 2014 1:51 am

by travelphotog

I would love a bigger and heaver one... But I have settled on the Shapeoko 2 with a Tinyg and 400w spindle. My main use for it is milling PCB boards. I have upgraded the Z axes with a Acme lead screw and nut. I would love to do a bit of plastic and maybe (VERY SLOWLY some 6061 1/8- 1/4" aluminum items. I also have to have it in my office in an enclosure due to lack work space outside of the house.

My main use for it is the PCB etching as i am pretty tired of acid etching and REALLY over all the drilling for my LED projects on the PCB boards.

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Sun Aug 10, 2014 8:35 am

by Eaglezsoar

travelphotog wrote:I would love a bigger and heaver one... But I have settled on the Shapeoko 2 with a Tinyg and 400w spindle. My main use for it is milling PCB boards. I have upgraded the Z axes with a Acme lead screw and nut. I would love to do a bit of plastic and maybe (VERY SLOWLY some 6061 1/8- 1/4" aluminum items. I also have to have it in my office in an enclosure due to lack work space outside of the house.

My main use for it is the PCB etching as i am pretty tired of acid etching and REALLY over all the drilling for my LED projects on the PCB boards.

Could you explain how to convert the pcb files into GCode for the router?

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Sun Aug 10, 2014 10:37 am

by travelphotog

I lay out the boards in a program called Copper Connection. I started with that program as it was a great tool for photo and toner transfer etching with acid. But it can also save the needed files to convert to the G Code for the router. I take the PCB GERBER file into a program called FlatCam

http://caram.cl/software/flatcam/ and it pretty much does all the rest for me. It will convert the files into the toolpath that the mill can understand. It will also level the working surface by cutting a shallow pocket which the board then drops into. It will do just isolation milling or it can be set to remove all the copper on the board but the traces you want. Just depends on the look you want and how much time you have and how big of a mess you want to clean up afterwards. You also import the GERBER file for the drilling points and it will then do the hardest part which is the drilling of the PCBs. Then when it is done it will cut the board out into any shape you desire and then you have a nice new board all ready for tinning and be populated.

As I do not have my personal mill yet, I have only done it a few times on a friend's mill. But it was a life saver for the large boards we were doing and the insane amount of holes I would have had to do on the drill press. As soon as I have my mill up and running I will gladly post pics and I will also be offering the PCB making services of the mill if anyone needs a board made.

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Sun Aug 10, 2014 10:41 am

by Eaglezsoar

travelphotog, thanks for the detailed answer.

A very good tutorial on how to get started.

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Sun Aug 10, 2014 11:03 am

by travelphotog

I am working on my heated and humidity controlled printer enclosure now. It will need a few boards made for the Arduino environmental control system. I will post the process with pics when I do. By the time I have the enclosure designed in CAD and the beta prints made and fitted, I should have my mill and can give you guys a good idea of how it mills the PCBs then.

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Mon Aug 11, 2014 9:54 am

by geneb

There's also a program called pcb-gcode that runs as a script within Eagle. It's open source and works pretty well.

g.

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Mon Aug 11, 2014 11:32 am

by travelphotog

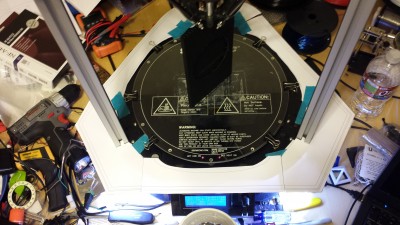

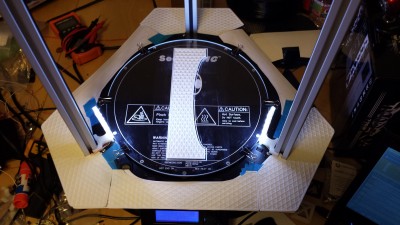

Well it was a really long night of CAD work.. But I knocked out a few things and among them was the lower part of my full build area enclosure. I just have to print the beta prototypes later today and get the final fittings worked out. Will have Arduino controlled full temp and humidity controls.

- A pattern fit of the new full build area enclosure. temp and humidity controls soon to come.

Sorry for the mess in the shot. I am still setting up the printer how I want to and printing off parts. This shot has the side ventilation panel that just finished as I was fitting the enclosure pattern to double check everything.

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Mon Aug 11, 2014 12:47 pm

by Eaglezsoar

geneb wrote:There's also a program called pcb-gcode that runs as a script within Eagle. It's open source and works pretty well.

g.

Oh No! I have scripts running inside me! I am doomed!

Re: Rostock Max V2 build with a few upgrades from the start.

Posted: Wed Aug 13, 2014 4:49 am

by travelphotog

OK a few updates...

I threw together a nice new home for my new best friend in CAD the other night.

- Box and insert for calibration dial.

- All nice and happy in a safe new home. That old cardboard box HAD to go.

- Beta panels for full build area enclosure fit check are all printed and everything fits perfectly!

I am now working on the upper fixture for the enclosure and the locking system to keep it all together without adding holes to the MAX. I should have more done shortly. Though I do have a few photo shoots to knock out in the next couple of days and also need to get hopping on my filament extruder this weekend. At the rate I am going through filament I am REALLY looking forward to getting that puppy up and running.