Version 26 is a winner?

I'll let you all be the judge of that, but I do have it successfully installed and the acrylic cover fits!

So, I'm attaching the STL files here. I'm using Slic3r for this with ABS obviously. It took about 2-3 hours to print, but I set my speed pretty low.

Hardware you'll need for this to work:

Qty. 6 — 8-32 x 1" long Thumb (Spade) Screws, or other similar thumbscrew. Bought mine here.

http://www.ebay.com/itm/331133117348

Qty. 6 — 8-32 Nylon Lock Nuts. These are for the thumbscrews listed above.

Qty. 3 — 6-32 x 2" long Pan Phillips Machine Screws. These are slightly longer screws to replace the bearing screws.

Qty. 3 — 6-32 Nylon Lock Nuts.

(Can simply reuse what you have.)

I wanted something that would install easily, allow easy adjustment, and minimize risk of damage to the printer. The top bracket installs by simply removing the nylon thumbscrew at the top of each tower. Once removed you'll notice that the top tensioner bracket will slide right into the gap that is present between the top melamine plate and the horizontal support for the tower supports.

Before you do anything, please take the time to file out the holes if needed, file the top piece where the support was printed, and build it all prior to installing. You want the thumbscrews to slide freely, and you DO NOT want them to thread the holes.

Once you have successfully dry fit everything, leave everything together except for the bearing screw. You want to install it with the top bracket and smaller bearing brackets together already, or else you'll find it's nearly impossible to install the thumbscrews after the fact. Slide the partially assembled tensioner bracket into the gap at the top of the tower supports, and tighten the Nylon Thumbscrew (original top screw). This will tighten the top tensioner bracket and hold it in place. Note: I made the hole slotted to allow some play, so you should be able to position it inward or outward to align the bearing bracket holes.

Now insert the 2" 6-32 screw through the left or right bearing bracket and the bearing assembly. Use the 6-32 nylon locknut on the other side and tighten it with a screwdriver. Make sure you don't over tighten it though. It really needs to be just tight enough so that the smaller bearing brackets do not have a huge gap between the melamine tower supports, and loose enough to allow the whole assembly to move up and down once you tighten the adjustment screws.

Adjust the thumbscrews now until the belt is tight. Once you feel it's tight enough, you can now tighten the bearing screw a little more. Don't overdue it though.

Photos:

- File away the residual support material.

- Installing nuts into top bracket. Use a screw to help press it in place.

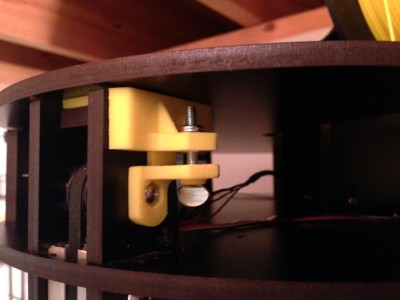

- Top bracket with nuts installed. Notice the slots inside each side wall. This is to allow the bearing brackets to move up and down, but limit rotation.

- Right side view. Note the smaller brackets are different. One is left and one is right.

- Front view of tensioner installed.

Files:

Here's the STL file, and I'll call it V.026.

I used Slic3r for this, and other than having to slightly file off burs from the support material, and opening up a few of the holes, it all fits pretty well. I'm not sure if my machine is 100% calibrated though, so you might need to adjust the scale of this in Repetier by a very small amount if you notice a poor fit. One other thing, you'll notice that I modeled the support material in the STL file. After 25 versions I figured out it was best to not rely on Slic3r to add support material. It should snap right off and you'll just need to sand or file where it was in place. If you guys feel you want it without the support material modeled, just let me know and I'll post an alternate.

Finally, I'm open to suggestions on how I can make this even better. I'm pretty happy with it right now, and time will tell if it holds up. Fingers crossed. Please let me know if you have any luck with this, and please post pics of it installed. If all goes well and you all like it, I'll eventually throw it up on Thingiverse.

Have a great Memorial weekend. I hope you all get the time to print some of these and post pics.