Page 2 of 21

Re: Trick Laser MAX METAL Build

Posted: Sat Mar 28, 2015 9:34 am

by Eaglezsoar

Mac The Knife wrote:Well, I just clicked the button.

Is it done yet?

I just clicked the button also and ask the same question,

is it done yet?

Re: Trick Laser MAX METAL Build

Posted: Sat Mar 28, 2015 1:52 pm

by ccavanaugh

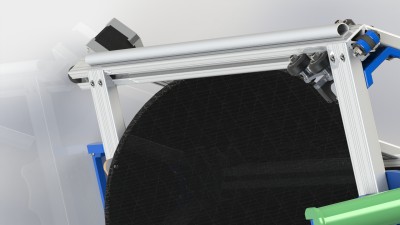

Spool holder complete... ugly, but should work just fine. Designed to laser cut or print. The arm is a lamination of two pieces which is the same approach as the SeeMe CNC arm.

Should also be out of 1/4-20 t-nuts and screws about now.

Non-alcoholic suggestions to un-ugly are welcome...

- Spool Holder

- Spool Holder front side

- Spool Holder back side

Re: Trick Laser MAX METAL Build

Posted: Sat Mar 28, 2015 3:12 pm

by teoman

The trend for printing extotic materials is to have them in a sealed box with some dessicant.

If i were designing a spool holder i would keep this in mind from the beginning.

Re: Trick Laser MAX METAL Build

Posted: Sat Mar 28, 2015 4:25 pm

by KAS

Something like this:

http://www.instructables.com/id/Techniq ... 4/Dry-Box/" onclick="window.open(this.href);return false;

but purpose built like it was intended for this machine.

Re: Trick Laser MAX METAL Build

Posted: Sat Mar 28, 2015 4:39 pm

by ccavanaugh

Good point on the moisture control and dry-box. It might be easier to adapt a container like the Instructable and create a bowden adapter for the extruder inlet to keep everything sealed well. I'm a bit concerned about the variation in spool sizes of the specially materials.

Will noodle that one over a bit.

Thanks!

Re: Trick Laser MAX METAL Build

Posted: Sat Mar 28, 2015 5:48 pm

by ccavanaugh

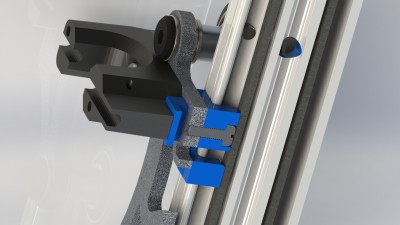

Details worked out for the belt spacer for the Trick Trucks. This keeps the belt parallel to the axis of motion so changes in angularity do not create print artifacts.

I've printed a test piece to verify strength at 1 mm, and everything appears to be good. I'm adding an extra precision washer to the Trick Truck to give an extra 1 mm of clearance which doubles the thickness of the test piece from 1 to 2 mm.

A small pin or screw is used to keep the belt spacer in place. A little super glue may be used also. I've shown a 2.5 mm screw which is a slip fit with the Trick Truck hole, but a 3/32 roll pin will press in place also. The local hardware store stocks the 2.5 mm screws which was a bonus. The spacer woks in conjunction with the clamp that Jim designed.

A side note: The stock SeeMe CNC belt path guides the belts very close to parallel to the trucks and a belt spacer is not needed. The MAX METAL frame simplifies the belt path greatly, but the belt sits much deeper inside the extrusion.

- Full Trick Truck assy

- Trick Truck top view

- Truck Truck - X-Section

Re: Trick Laser MAX METAL Build

Posted: Sun Mar 29, 2015 8:28 am

by plasma

Ccavanaugh,

To start off I have to tell you how impressed i am with your work and a bit envious.

I have ordered the Max Metal kit and was wondering if you will make your STL files available. I would love to start printing some of the parts, before the kit arrives.

Vitaly

Re: Trick Laser MAX METAL Build

Posted: Sun Mar 29, 2015 10:48 am

by ccavanaugh

plasma wrote:Ccavanaugh,

To start off I have to tell you how impressed i am with your work and a bit envious.

I have ordered the Max Metal kit and was wondering if you will make your STL files available. I would love to start printing some of the parts, before the kit arrives.

Vitaly

Thanks!

The link to the printable files are now in my signature. I've not printed a complete set yet, so tread carefully!

Re: Trick Laser MAX METAL Build

Posted: Sun Mar 29, 2015 3:20 pm

by Eaglezsoar

I just wanted you to know that your hard work on creating the parts is appreciated.

Your kind gesture of releasing them to this forum expecting nothing in return is fantastic and everyone who

downloads them owes you a word of thanks!

Re: Trick Laser MAX METAL Build

Posted: Sun Mar 29, 2015 4:50 pm

by ccavanaugh

Eaglezsoar wrote:I just wanted you to know that your hard work on creating the parts is appreciated.

Your kind gesture of releasing them to this forum expecting nothing in return is fantastic and everyone who

downloads them owes you a word of thanks!

Thanks Eagle, much appreciated!

I believe in opensource development and collaboration. I expect others will work with the files and see opportunities to improve upon what I've done. It's a continuous cycle everyone wins from.

This is all based on the great foundation that Brian laid. Without the availability of a metal frame, I would still be poking around at my own design I was not too happy with. Brian nailed it with the simplicity of the design.

Re: Trick Laser MAX METAL Build

Posted: Sun Mar 29, 2015 5:09 pm

by plasma

The designs are great and very professional. Thank you for your hard work and letting people like me benefit, who has zero experience in CAD. I believe strongly in opensource development, but it only works because of ppl like you, and many others on this forum.

Re: Trick Laser MAX METAL Build

Posted: Sun Mar 29, 2015 6:50 pm

by Thinker

ccavanaugh wrote:plasma wrote:Ccavanaugh,

To start off I have to tell you how impressed i am with your work and a bit envious.

I have ordered the Max Metal kit and was wondering if you will make your STL files available. I would love to start printing some of the parts, before the kit arrives.

Vitaly

Thanks!

The link to the printable files are now in my signature. I've not printed a complete set yet, so tread carefully!

Ccavanaugh - I was on the fence about jumping on the Metal Max frame bandwagon. I was going to wait and hope Brian would sell a more complete kit with end stops/bed mounts. Your work and generosity has pushed me over the edge. Brian should be giving you some sort of kickback!

Now I'm patiently waiting for my box of shiny new parts to arrive!

Re: Trick Laser MAX METAL Build

Posted: Mon Mar 30, 2015 5:15 am

by ccavanaugh

Some completed test prints..

- Small Piece check prints

- Power Supply and EZStruder bracket

Re: Trick Laser MAX METAL Build

Posted: Mon Mar 30, 2015 8:41 am

by bvandiepenbos

Mac The Knife wrote:Brian, What if the X and Y towers were mirrored, that way both motors would hang towards the rear? Is that easily doable?

Then we need to make rights & lefts, I did not think it was worth the extra complexity from a production stand point. I want the parts count as low as possible.

How important is the motor orientation really?

Re: Trick Laser MAX METAL Build

Posted: Mon Mar 30, 2015 8:51 am

by Mac The Knife

It's not a game changer,,,, I was just looking at having a clean front.

Re: Trick Laser MAX METAL Build

Posted: Mon Mar 30, 2015 9:13 am

by bvandiepenbos

Eaglezsoar wrote:Mac The Knife wrote:Well, I just clicked the button.

Is it done yet?

I just clicked the button also and ask the same question,

is it done yet?

I DO have to sleep just a little ya know

Thanks all for your great response.

BIG thanks to Ccavanaugh for the design work on the "transplant" brackets and such. Very professional. Very generous of you sharing the .stl files also.

Re: Trick Laser MAX METAL Build

Posted: Mon Mar 30, 2015 10:08 am

by mvansomeren

ccavanaugh wrote:Spool holder complete... ugly, but should work just fine. Designed to laser cut or print. The arm is a lamination of two pieces which is the same approach as the SeeMe CNC arm.

Should also be out of 1/4-20 t-nuts and screws about now.

Non-alcoholic suggestions to un-ugly are welcome...

Spool Holder.JPG

Spool Holder Front side.JPG

Spool Holder - Backside.JPG

Maybe design a round spool holder arm that spins freely? IMO, the SeeMeCNC arm works but just barely. There are many times when the spool will get hung up momentarily to then suddenly release, shaking the entire printer. Over time the spools wear groves into the arm as well exacerbating the problem. Having a freely spinning arm would be a massive improvement that would match the improvement that the metal frame brings.

Re: Trick Laser MAX METAL Build

Posted: Mon Mar 30, 2015 6:55 pm

by ccavanaugh

mvansomeren wrote:

Maybe design a round spool holder arm that spins freely? IMO, the SeeMeCNC arm works but just barely. There are many times when the spool will get hung up momentarily to then suddenly release, shaking the entire printer. Over time the spools wear groves into the arm as well exacerbating the problem. Having a freely spinning arm would be a massive improvement that would match the improvement that the metal frame brings.

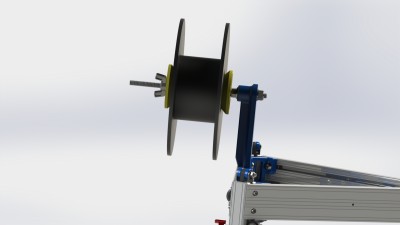

I've added a "wrapper" of sorts that address your concern. I used a very similar part on my v1 will good success. The bonus is different wrappers can be made for different spool sizes.

- Spool Holder 2

Re: Trick Laser MAX METAL Build

Posted: Mon Mar 30, 2015 7:12 pm

by forrie

I currently use something very similar to this for spool holding.

http://www.thingiverse.com/thing:577405" onclick="window.open(this.href);return false;

It's smooth as butter with the 608 bearings. I'll probably do the same when my shiny new frame arrives.

Re: Trick Laser MAX METAL Build

Posted: Mon Mar 30, 2015 7:46 pm

by ccavanaugh

The last significant bits are to sort out wire routing. The easiest approach I've been able to conceive is to use some peel and stick wire track. This will route the extruder wires, hot end power, fans, etc. to the top of the frame. Menard's carries the round version shown and Lowe's has a 3/4" wide by 1/2" deep rectangular version with more room inside.

Option B is to use Geneb's extrusion clip and dowel approach used in the v1 assembly manual.

- Wire track

End stop wiring can go down the inner diameter of each tower extrusion with a couple of cross holes drilled close to the horizontals to avoid crossing paths with the belts and trucks. The exit holes can be placed on the eccentric side of the truck to allow a full range of motion. I'm considering designing up a drill guide to make hole placement easy and clean.

Other ideas?

Re: Trick Laser MAX METAL Build

Posted: Mon Mar 30, 2015 7:48 pm

by ccavanaugh

forrie wrote:I currently use something very similar to this for spool holding.

http://www.thingiverse.com/thing:577405" onclick="window.open(this.href);return false;

It's smooth as butter with the 608 bearings. I'll probably do the same when my shiny new frame arrives.

Good point. There will be left over belt idler bearings from a conversion, maybe those can be put to use....

Re: Trick Laser MAX METAL Build

Posted: Tue Mar 31, 2015 9:33 am

by mvansomeren

ccavanaugh wrote:mvansomeren wrote:

Maybe design a round spool holder arm that spins freely? IMO, the SeeMeCNC arm works but just barely. There are many times when the spool will get hung up momentarily to then suddenly release, shaking the entire printer. Over time the spools wear groves into the arm as well exacerbating the problem. Having a freely spinning arm would be a massive improvement that would match the improvement that the metal frame brings.

I've added a "wrapper" of sorts that address your concern. I used a very similar part on my v1 will good success. The bonus is different wrappers can be made for different spool sizes.

Spool Holder 2.JPG

I'm actually using something very similar but the spools still get hung up, unfortunately.

forrie wrote:I currently use something very similar to this for spool holding.

http://www.thingiverse.com/thing:577405" onclick="window.open(this.href);return false;

It's smooth as butter with the 608 bearings. I'll probably do the same when my shiny new frame arrives.

This is more along the way I was thinking, although with a piece that fits or locks into the stand without the need of tie wraps would be nice.

Re: Trick Laser MAX METAL Build

Posted: Tue Mar 31, 2015 12:29 pm

by bvandiepenbos

It is a tight fit, but a 22 awg 8 conductor cable will pass through the center hole. On Rostock MAX builds I run one up each tower which gives me 24 wires up top, enough for everything. Make sure the wires you pick for endstops are not in the same tower as stepper motor wires... weird things happen.

Z tower wire = 6 for endstops, 2 for thermistor

Y tower wire = 4 for extruder motor, 2 for barrel fan, 2 for part fan

X tower wire = 2 for hot end +, 2 for hot end -, 2 for light ring, 2 spares

For this MAX METAL frame you will have to drill some cross access holes like ccavanaugh suggested.

His idea using the surface mount wire conduit would be easier.

You can create a wire passage by sliding a thin strip of plastic about 1/2"-9/16" wide in the t-slot, the v-wheels do not ride deep enough in slot to interfere. Someone on this forum had the clever idea of using plastic banding used for packaging, I think he got some at the UPS store.

Re: Trick Laser MAX METAL Build

Posted: Tue Mar 31, 2015 5:59 pm

by ccavanaugh

bvandiepenbos wrote:It is a tight fit, but a 22 awg 8 conductor cable will pass through the center hole. On Rostock MAX builds I run one up each tower which gives me 24 wires up top, enough for everything. Make sure the wires you pick for endstops are not in the same tower as stepper motor wires... weird things happen.

Z tower wire = 6 for endstops, 2 for thermistor

Y tower wire = 4 for extruder motor, 2 for barrel fan, 2 for part fan

X tower wire = 2 for hot end +, 2 for hot end -, 2 for light ring, 2 spares

For this MAX METAL frame you will have to drill some cross access holes like ccavanaugh suggested.

His idea using the surface mount wire conduit would be easier.

You can create a wire passage by sliding a thin strip of plastic about 1/2"-9/16" wide in the t-slot, the v-wheels do not ride deep enough in slot to interfere. Someone on this forum had the clever idea of using plastic banding used for packaging, I think he got some at the UPS store.

Even better. Even if the wheels were to touch the banding, I don't think it would create any measurable resistance.

Re: Trick Laser MAX METAL Build

Posted: Tue Mar 31, 2015 8:14 pm

by ccavanaugh

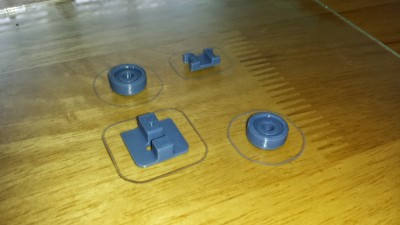

Gen 2 spool holder...

It uses 2 of the 608 Bearings. 5/16" or 8mm threaded rod will work.

- Gen 2 Spool Holder - Back profile

- Gen 2 Spool Holder - Side profile

I have ordered the Max Metal kit and was wondering if you will make your STL files available. I would love to start printing some of the parts, before the kit arrives.

I have ordered the Max Metal kit and was wondering if you will make your STL files available. I would love to start printing some of the parts, before the kit arrives.